Every Part

Every Industry

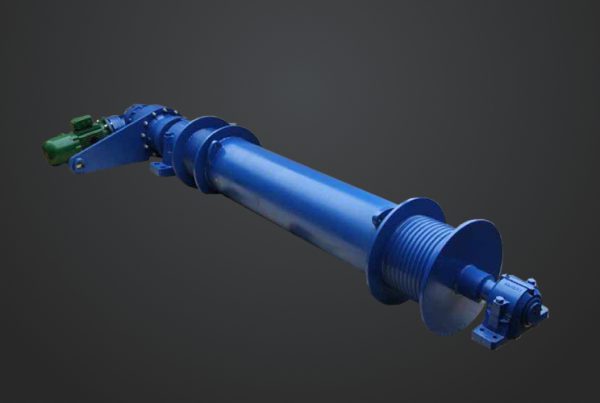

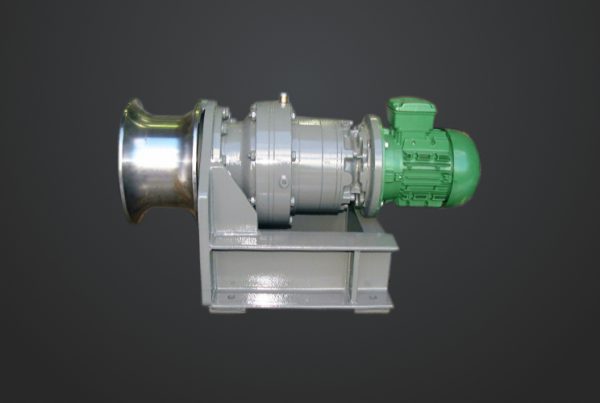

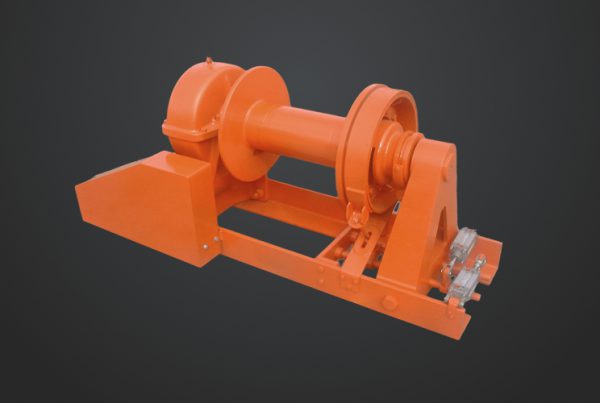

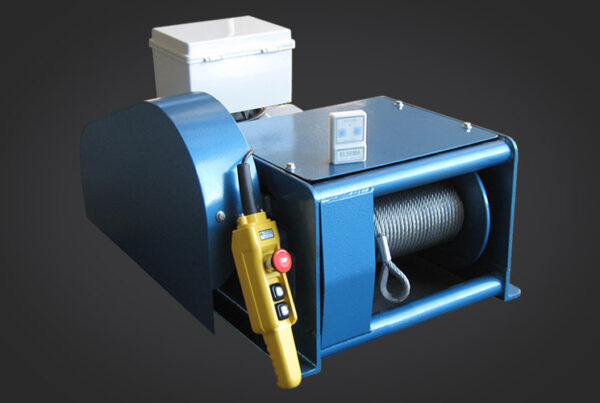

We specialise in the manufacture of OEM parts conforming to all industry, national and inter-national standards required. See below for a range of our more common product applications. If you require custom made components for your project don’t hesitate to get in-touch with us to discuss your requirements today.